BHP

2008

Newman West

Saracen

In November 2007, Consep embarked on a pivotal project – the design and supply of three heavy-duty hydraulic drive linear samplers for BHP's Mt Whaleback Hub. The challenge was multifaceted: crafting samplers that met stringent ISO3082:2009 standards while seamlessly operating within the harsh climatic conditions of the Newman region. The critical requirement was maintaining constant cutter speed, regardless of the extreme temperature fluctuations typical in this area.

The Newman region is characterised by temperature extremes, with temperature swings of up to 30°C between night and day. Such fluctuations result in significant changes in oil viscosity, which, in turn, affect the cutter's speed throughout the day. Consep needed to devise a solution that would not only meet but exceed ISO3082 requirements, actively controlling speed within a remarkable +/- 1% tolerance.

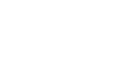

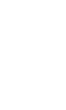

Consep's innovative solution revolved around the supply of high-capacity hydraulic drive samplers, each serving distinct functions: fines, lump and the Satellite Ore Body (SOB). The cornerstone of this solution was a bespoke hydraulic system meticulously designed to provide a known and programmable cutter speed.

What set this hydraulic system apart was its remarkable adaptability. It could respond instantaneously to varying loads and oil viscosity changes triggered by temperature fluctuations. This adaptability ensured that the cutter maintained a consistent speed, a feat that surpassed ISO3082 standards.

The culmination of this project occurred in July 2009 when Consep successfully commissioned the three hydraulic drive linear samplers, each tailored to specific duties: SOB, Fines and Lump. These samplers proved to be robust and reliable, effectively overcoming the challenges posed by extreme temperature variations in the Newman region.

Their ability to ensure consistent and high-precision ore sampling made them invaluable to BHP's operations. Once again, Consep's unwavering commitment to engineering excellence and innovative solutions was evident in this project.

Contact us to discuss how you could benefit from 30+ years of manufacturing and engineering expertise.