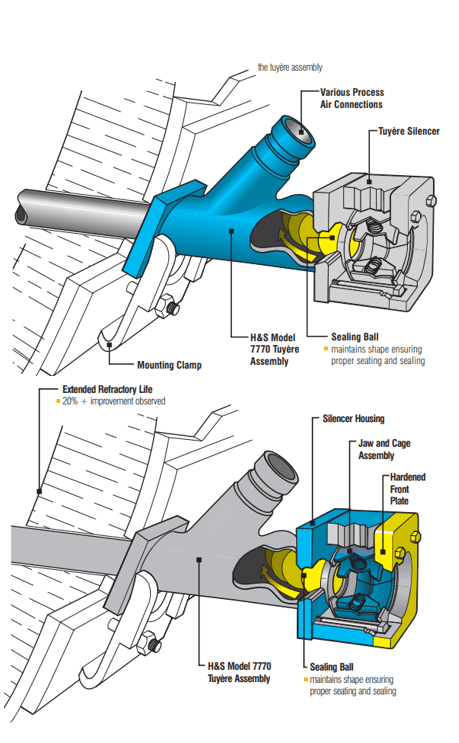

The ability to adjust the tuyeres vertically compensates for furnace deflection “belly sag” which occurs between the riding rings as the converter ages, thus always allowing for a straight tuyere line rather than following the vessels shape. Punching then becomes easier and refractory life is extended by eliminating off centre punching of the tuyere. A Consep Tuyere ensures this.

When the punch bar is inside the tuyere clearing accretions, the ball valve is opened, and process air escapes out the tuyere. This blowback is loud and is hot air carrying sparks and small, very hot, matte particles. This is a big safety hazard and also draws material back into the tuyere “the siphon effect” when the punch bar is retracted creating a new blockage. A properly matched model 6570 Tuyere Silencer seals around the punch bar minimizing this escaping air which improves safety, less punching is required which reduces maintenance and air consumption, and blowing rates improve.

Contact us to discuss how you could benefit from 30+ years of manufacturing and engineering expertise.