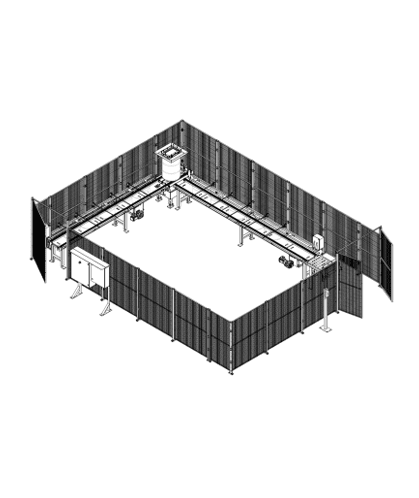

Consep’s Sample Collectors are used extensively in sampling applications throughout the world, and provide an automated method of collecting process plant, train loadout or shiploader samples. Consep offers a range of sample collector models to suit every sampling regime from 2 canister diverters to 24 bucket capacity collectors. Consep’s meticulous design approach to our sample collectors protects samples from moisture loss and contamination from dust ensuring high quality samples are delivered to the laboratory for sample preparation and analysis.

Speak to us about our latest innovation in sampling technology – the Linear Sample Collector featuring automated bucket and lid denesting, weight monitoring of sample increments and isolation-free interface for sample plant operators.

Contact us to discuss how you could benefit from 30+ years of manufacturing and engineering expertise.